Brief Description of Selective Study Case No. 7:

The age of each of the elevated Carbon Steel Tank Silos was approximately 25 years old. They stored and operated a hot mix solution of calcium hydroxide and water. Engineering assessment inspections identified many corrosion problems, structural deterioration, and imperfect and irregular welds on the substrate to be coated.

PRODUCT APPLICATION

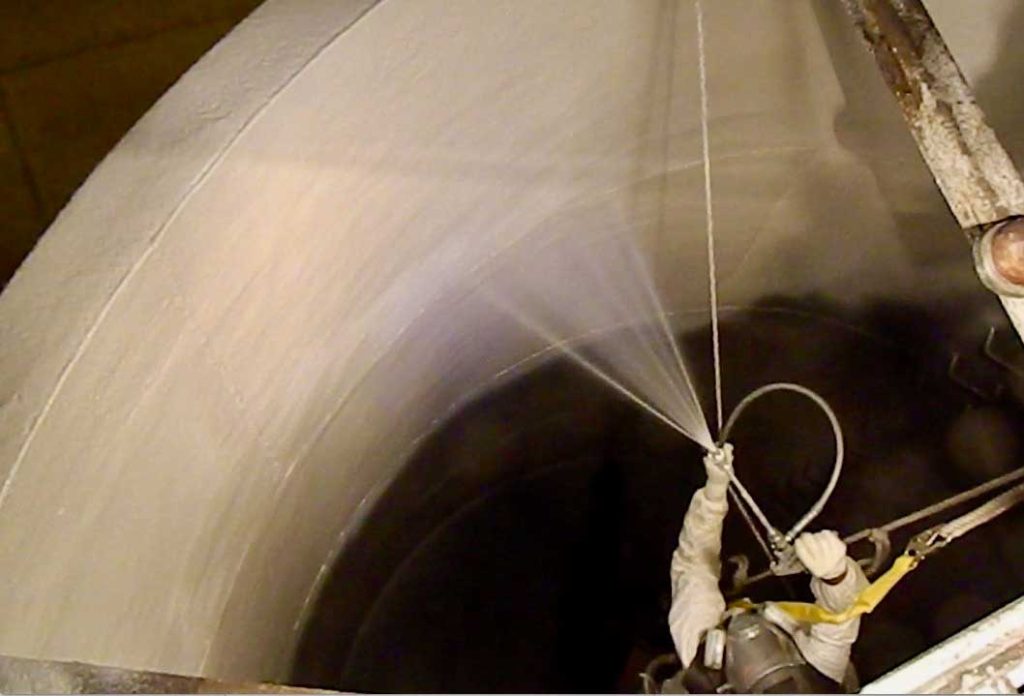

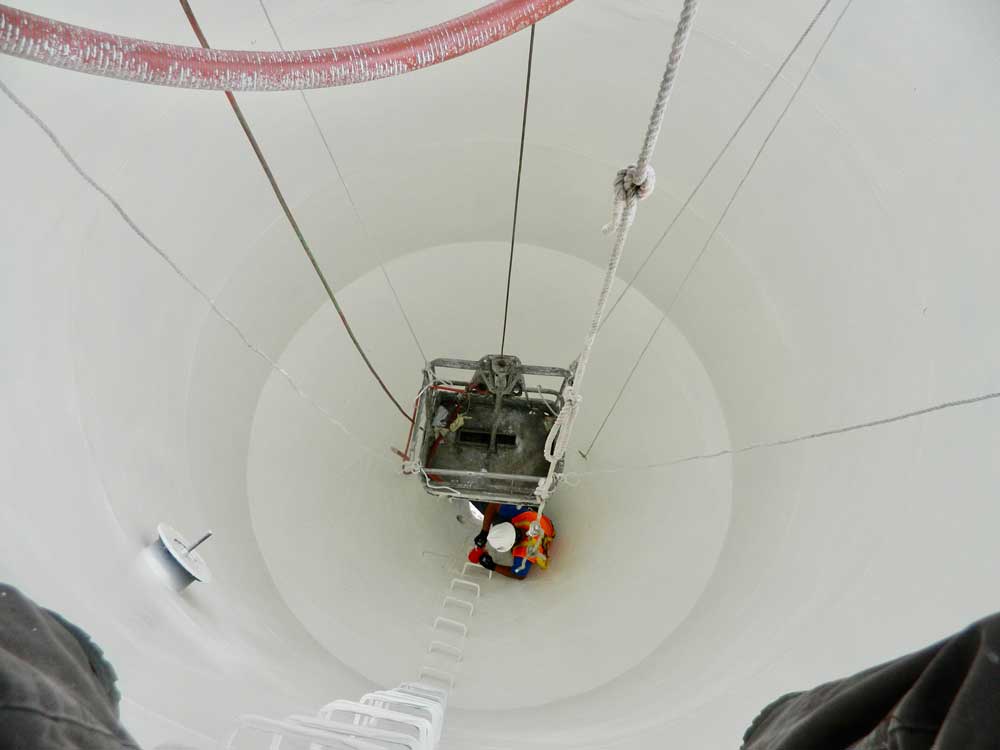

As part of the surface preparation, high and ultra-high pressure jets of water (Range: 25,000 to 40,000 Psi) were applied to the silo internals for removing deposits of Calcium Hydroxide, which was solidified and strongly adhered to the substrate of the two tanks. Subsequently, a wet sandblasting surface preparation was done to generate the anchoring profile and required cleanliness for applying the coating. All required structural repairs were performed, including removal of imperfect and irregular welds were removed. The Warren Epoxy was sprayed, and the average coating thickness was 1/8” (3 millimeters). Quality Control & Quality Assurance and inspections were performed and they all passed with outstanding values.

CONCLUSION

The Impermeabilization and Rehabilitation Project of the two silos were successfully executed in ten (10) days, in a quality and cost-effective manner, with no safety issues, and within the agreed work schedule with the customer. During the implementation of the project, the plant was able to continue operating at 50% capacity without stopping production. MADERO’s execution of this turnkey Mission Critical Project was a total success.