MISSION CRITICAL PROJECT No. 11:

ANGRA NUCLEAR POWER PLANT, UNITS 1 & 2, ARE LOCATED AT THE CENTRAL NUCLEAR ALMIRANTE ÁLVARO ALBERTO (CNAAA) COMPLEX ON THE ITAORNA BEACH IN ANGRA DOS REIS, RIO DE JANEIRO, BRAZIL. ANGRA 2 HAS A NET OUTPUT OF 1,275 MWE, AND IT WAS FIRST CONNECTED TO THE POWER GRID IN 2000 (FIG. 1). ANGRA 2 HAS AN AVERAGE CAPACITY FACTOR OF ABOUT 90%. THAT MEANS THAT UNIT 2 IS OPERATING NON-STOP 90% OF THE TIME THROUGHOUT THE YEARS.

ON JUNE 26TH, 2013, MADERO ENGINEERS, ARCHITECTS & CONSTRUCTORS PERFORMED A TURNKEY COATING APPLICATION JOB FOR PROVIDING CORROSION PROTECTION TO A BYPASS GATE VALVE THAT BELONGED TO THE CIRCULATING WATER SYSTEM FOR MAIN CONDENSER COOLING AT ANGRA 2 (FIG. 2). MADERO APPLIED THEIR EXCLUSIVE SINGLE COAT & RAPID CURE, MILITARY GRADE, U.S. NAVY AND AMERICAN BUREAU OF SHIPPING (ABS) CERTIFIED, WARREN EPOXY (ALSO KNOWN AS EPOXY ULTRA+® COATING IN BRAZIL & REST OF LATIN AMERICA).

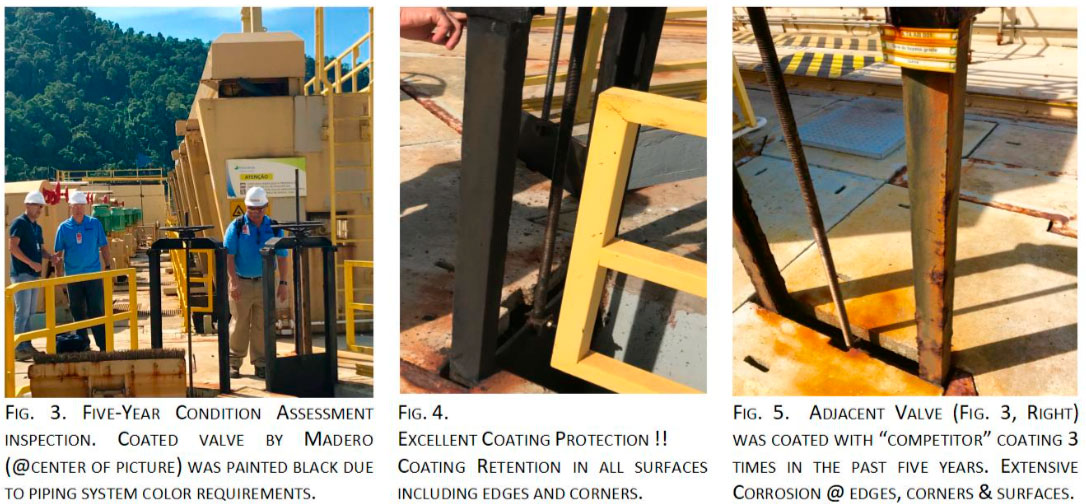

THE COATED BYPASS GATE VALVE IS LOCATED ADJACENT TO SIX TRAVELLING TRASH RACK EQUIPMENT (FIG. 3), WHICH IS USED FOR REMOVING DEBRIS AND SOLIDS FROM ATLANTIC OCEAN SEAWATER USED FOR COOLING THE MAIN CONDENSER. THE VALVE IS ALSO SUSCEPTIBLE TO THE ULTRA VIOLET RAYS FROM THE SUN, BECAUSE IT IS LOCATED ON AN OPEN ENVIRONMENT AND WITHOUT ANY PROTECTION FROM THE HARSH ENVIRONMENTAL CONDITIONS. THE TRAVELLING TRASH RACK EQUIPMENT HAS A SPRAY SYSTEM FOR CLEANING THE TRAVELLING RACKS. PART OF THIS HIGH SALT CONTENT SPRAY WATER ESCAPES TO THE ENVIRONMENT, AND CREATES AN EXTREMELY HUMID AND CORROSIVE ENVIRONMENT FOR THE ADJACENT BYPASS GATE VALVES, FIG 3.

ON JANUARY 24TH, 2018, MADERO AND ELETROBRAS STAFF PERFORMED A FIVE (5) YEAR CONDITION ASSESSMENT INSPECTION OF THE COATED BYPASS GATE VALVE. AFTER ALMOST FIVE YEARS OF OPERATING UNDER EXTREME CORROSIVE MARINE ENVIRONMENT, THE ELETROBRAS STAFF STATED THAT THE EPOXY ULTRA+® COATING WAS FOUND TO BE IN EXCELLENT CONDITIONS AND PROVIDED OUTSTANDING CORROSION PROTECTION.

IT IS IMPORTANT TO NOTE THAT ELINELTON PEREIRA DA SILVA, ANGRA COATING SUPERVISOR, WITNESSED THE EPOXY ULTRA+® COATING APPLICATION BACK IN 2013, AND ALSO PARTICIPATED DURING THE CURRENT CONDITION ASSESSMENT INSPECTION ACTIVITY WITH ENGR. FRANK MADERO (PRESIDENT OF MADERO), AND ENGR. GUILHERME HENRIQUE DOS S. ANDRADE FROM ELETROBRAS. TESTIMONIAL LETTER WAS WRITTEN BY SUPERVISOR ELINELTON PEREIRA TO DOCUMENT THE EXCELLENT AS-FOUND CONDITION AND UNRIVALED WORLD CLASS PERFORMANCE TO DATE BY THE EPOXY ULTRA+® AFTER FIVE (5) YEARS OF CONTINUOUS PROTECTION OF THE VALVE IN AN EXTREMELY CORROSIVE MARINE ENVIRONMENT AT THE ATLANTIC OCEAN INTAKE BAY.