There is nothing to show here!

Slider with alias home-factory not found.

Electrical Engineering

We have experience serving as a clients’ single point of contact under a design build delivery format.

Industrial Automation

We have experience serving as a clients’ single point of contact under a design build delivery format.

Mechanical Engineering

We have experience serving as a clients’ single point of contact under a design build delivery format.

Byron manufactures high-quality products

We’re a company leader in manufacturing, exporting, international trading and local supplying services of various commodities.

Our goal is manufacture good quality products.

Review functions of equipments and tools.

Innovative manufacturing methods.

A solid experience in iron and steel plants.

An Independent Engineering Design and Services company

We specialize in the areas of engineering and manufacturing

We are one of the leading end-to-end engineering services & solutions company offering business value across the entire product lifecycle.

Engineering

We are one of the leading end-to-end engineering services and solutions company in the world.

Manufacturing

We are one of the leading end-to-end engineering services and solutions company in the world.

Oil & Gas

We are one of the leading end-to-end engineering services and solutions company in the world.

Industrial

We are one of the leading end-to-end engineering services and solutions company in the world.

Automotive

We are one of the leading end-to-end engineering services and solutions company in the world.

Construction

We are one of the leading end-to-end engineering services and solutions company in the world.

Strengthening the competitive edge and standardization of the processes

Trusted partner to Fortune 500 companies delivering qualitative, simplified and cost-effective solutions

Solutions to the challenges of the evolving and industry

We specialize in the areas of engineering, digital technology and manufacturing. Our customers have used our experience and expertise, to control their costs and improve efficiency.

Construction Workers

+

Completed Projects

+

Completed Projects

+

Worldwide Branches

+

Our extensive resume is comprised of over 3,500 projects completed

Our diverse project list includes commercial buildings, manufacturing products and technology

Project item not found!

Structural Rehabilitation & Impermeabilization of two structurally deteriorated elevated steel tank silos a the medicinal gas manufacturing plant ACROMAX.

Brief Description of Selective Study Case No. 7:

The age of each of the elevated Carbon Steel Tank Silos was approximately 25 years old. They stored and operated a hot mix solution

of calcium hydroxide and water. Engineering assessment inspections identified many corrosion problems, structural deterioration, and

imperfect and irregular welds on the substrate to be coated.

Subsequently, a wet sandblasting surface preparation was done to generate the anchoring profile and required cleanliness for applying the

coating. All required structural repairs were performed, including removal of imperfect and irregular welds were removed. The Warren Epoxy was sprayed, and the average coating thickness was 1/8” (3 millimeters). Quality Control & Quality Assurance and inspections

were performed and they all passed with outstanding values.

manner, with no safety issues, and within the agreed work schedule with the customer. During the implementation of the project, the plant was able to continue operating at 50% capacity without stopping production. MADERO’s execution of this turnkey Mission Critical Project was a total success.

of calcium hydroxide and water. Engineering assessment inspections identified many corrosion problems, structural deterioration, and

imperfect and irregular welds on the substrate to be coated.

PRODUCT APPLICATION

As part of the surface preparation, high and ultra-high pressure jets of water (Range: 25,000 to 40,000 Psi) were applied to the silo internals for removing deposits of Calcium Hydroxide, which was solidified and strongly adhered to the substrate of the two tanks.Subsequently, a wet sandblasting surface preparation was done to generate the anchoring profile and required cleanliness for applying the

coating. All required structural repairs were performed, including removal of imperfect and irregular welds were removed. The Warren Epoxy was sprayed, and the average coating thickness was 1/8” (3 millimeters). Quality Control & Quality Assurance and inspections

were performed and they all passed with outstanding values.

CONCLUSION

The Impermeabilization and Rehabilitation Project of the two silos were successfully executed in ten (10) days, in a quality and cost-effectivemanner, with no safety issues, and within the agreed work schedule with the customer. During the implementation of the project, the plant was able to continue operating at 50% capacity without stopping production. MADERO’s execution of this turnkey Mission Critical Project was a total success.

Corrosion & Impermeabilization Protection, Structural Rehabilitation/Repair of Semi Deteriorated & Fully Deteriorated Metallic & Concrete

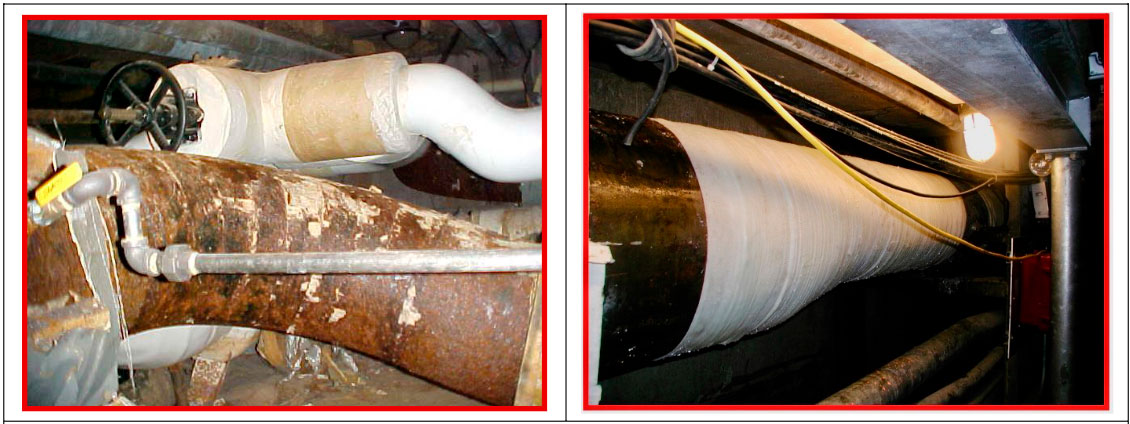

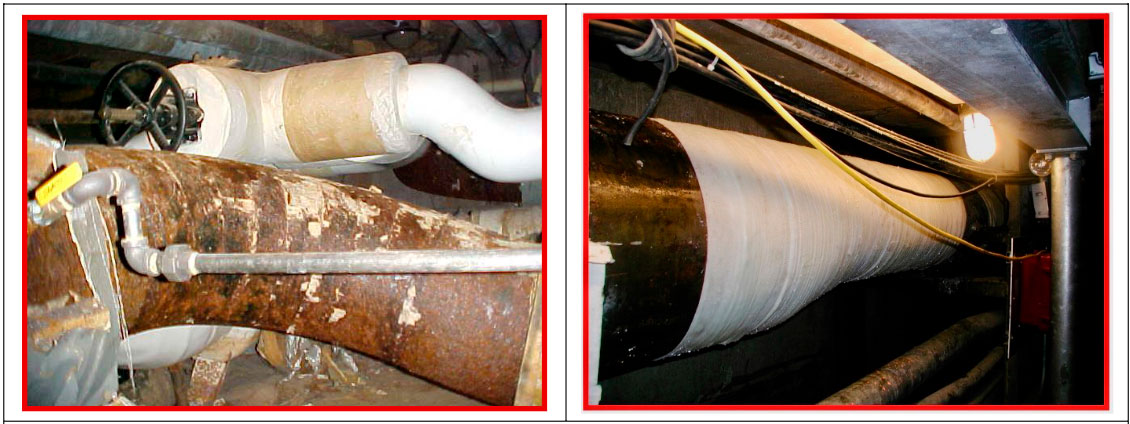

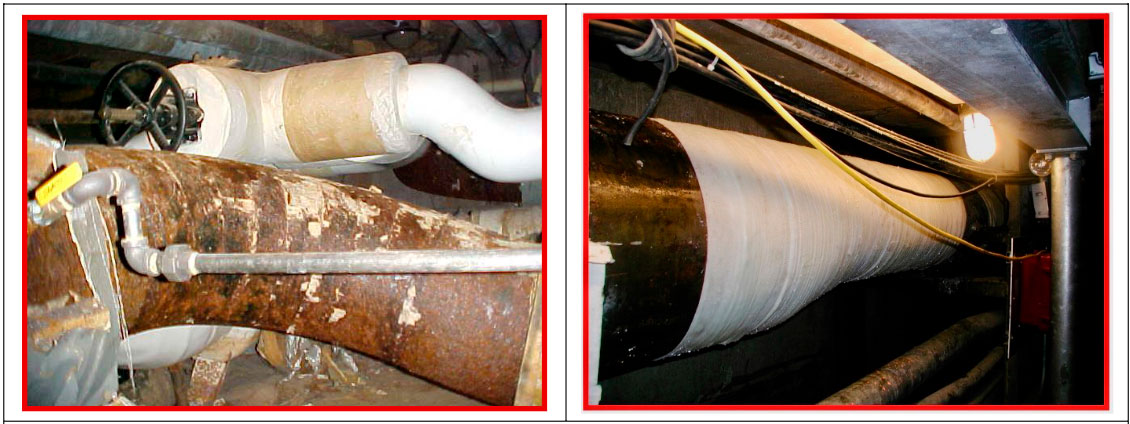

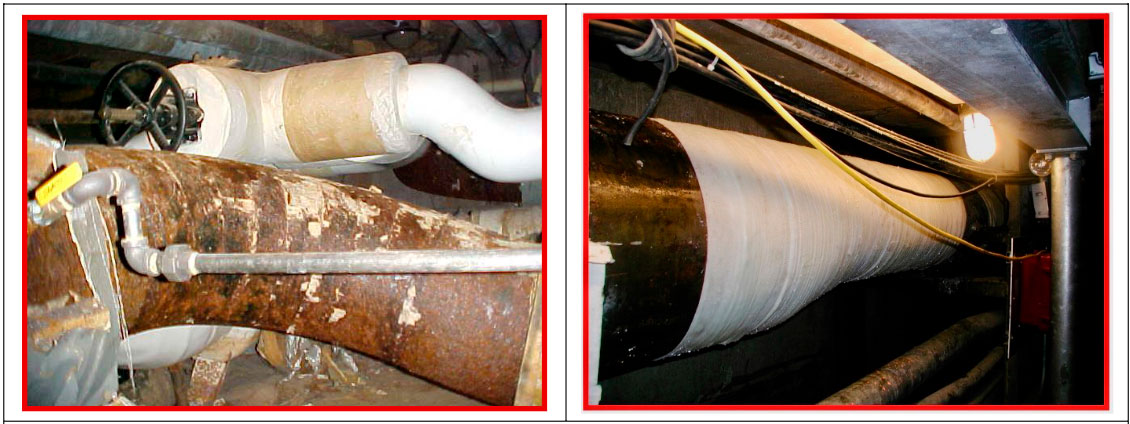

Brief Description of Selective Study Case No. 6:

Process Piping Systems & Component with Rapid Cure, Smart & Durable Engineered Composite Pipe Repair Systems.

Pics. 1 & 2: Composite Structural Rehab/Repair of Fully Deteriorated 12” Dia. Corroded Pipe w/ Pinholes

Pics. 3 & 4: Composite Structural Rehab/Repair of Fully Deteriorated 14” Dia. Corroded Pipe w/ Pinholes

Pics. 5 & 6: Composite Structural Rehab/Repair of Semi Deteriorated 54” Dia. Corroded Pipe w/ 63% Wall Loss

Corrosion Protection Coating Application at Market Center Lift Station’s Atmospheric and Immersion

Brief Description of Selective Study Case No. 5:

Piping Systems at City of Terrell, Texas.

Per owner’s coating specification, Immersion Piping System required application of three layers of Sherwin Williams Macropoxy coating system (i.e. primer, intermediate, and topcoat). Atmospheric Piping System also required first two layers of Sherwin Williams’ Macropoxy coating and Polyurethane topcoat. MADEROs Scope Of Work also included Abrasive Surface Preparation with Dustless Sponge Jet Abrasive System, Quality Control Testing (e.g. Wet Gauge, Holiday, and Adhesion Pull) and Quality Assurance.

Per owner’s coating specification, Immersion Piping System required application of three layers of Sherwin Williams Macropoxy coating system (i.e. primer, intermediate, and topcoat). Atmospheric Piping System also required first two layers of Sherwin Williams’ Macropoxy coating and Polyurethane topcoat. MADEROs Scope Of Work also included Abrasive Surface Preparation with Dustless Sponge Jet Abrasive System, Quality Control Testing (e.g. Wet Gauge, Holiday, and Adhesion Pull) and Quality Assurance.

Major Structural Engineered Rehabilitation & Repair, and Structural Optimization of Fully Deteriorated Buried 96” Diameter Concrete Piping & 4’x4’ Square Concrete Manhole Structures.

Brief Description of Selective Study Case No. 4:

using Warren Structural Epoxy for Long Term Useful Operational Life. Asset Owner: City of Fort Worth. The newly Engineered Protective, Structural Rehabilitation & Repair provided full structural integrity plus additional benefits (but not limiting to):

A. Able to withstand all the applicable structural design basis loads of soil and hydro loads.

B. A durable barrier against potential Inflow / Infiltration (I/I) of groundwater and stormwater, and hydrogen sulfide attack.

C. Pipe flow capacity increase due to Warren Epoxy’s Low Coefficient Of Roughness (COF) Vs. Deteriorated Concrete’s High COF.

The following pictures provide a view of their As-Found & As-Left Conditions of the Rehabilitated/Repaired Structures:

B. A durable barrier against potential Inflow / Infiltration (I/I) of groundwater and stormwater, and hydrogen sulfide attack.

C. Pipe flow capacity increase due to Warren Epoxy’s Low Coefficient Of Roughness (COF) Vs. Deteriorated Concrete’s High COF.

The following pictures provide a view of their As-Found & As-Left Conditions of the Rehabilitated/Repaired Structures:

Major Structural Engineered Rehabilitation & Repair of a Structurally Deteriorated Sewer Treatment Plant located at an island in the Gulf of Mexico, Galveston County, Texas.

Brief Description of Selective Study Case No. 3:

In May 2019, MADERO Provided Turnkey Certified Engineering Design / Installation / QA & QC Testing & Inspections of MADERO’s Structural Warren Epoxy Liner on Wastewater Sewer Treatment Tanks (e.g. Clarifier, Aeration Basin, Digester, Chlorine Contact Chambers), Concrete/Brick Manholes, and Metal Pipes & Structural Beams. MADERO also applied Polyurethane Coating in specific atmospheric areas & Performed Inflow & Infiltration (I/I) Structural Repairs.

he plant was constructed around 2014. After five years of operation, its concrete and metal structures had accelerated corrosion & structural deterioration due to the surrounding aggressive marine environment, and hydrogen sulfide attack from processing sewer wastewater. Furthermore, in 2017, the sewer structures were coated with an elastomeric protective coating. After two years of service, the coating was fully deteriorated and delaminating.

In May 2019, MADERO Provided Turnkey Certified Engineering Design / Installation / QA & QC Testing & Inspections of MADERO’s Structural Warren Epoxy Liner on Wastewater Sewer Treatment Tanks (e.g. Clarifier, Aeration Basin, Digester, Chlorine Contact Chambers), Concrete/Brick Manholes, and Metal Pipes & Structural Beams. MADERO also applied Polyurethane Coating in specific atmospheric areas & Performed Inflow & Infiltration (I/I) Structural Repairs.

Major Structural Engineered Rehabilitation & Repair, and Structural Optimization of Fully Deteriorated Stormwater Piping System Stadium

Brief Description of Selective Study Case No. 2:

Uusing Structural Epoxy and High Strength Carbon Reinforced Polymer for Structurally Robust Long Term Useful Operational Life.

Asset Owner: University of Tennessee. The buried Non-Structural Shotcrete Stormwater Piping System segment was located about 60 feet below ground of 100+ years old Neyland Stadium, in Knoxville, Tennessee. The newly Engineered Protective and Structural Composite Piping System provides full structural integrity plus additional benefits (but not limiting to):

a. Able to withstand all the applicable structural design basis loads of soil and hydro loads.

b. High strength Carbon Fiber Reinforced Polymer provides a more robust long-term operating life by protecting the

new composite pipe with resistance to creep rupture and fatigue failure.

c. A durable barrier against potential Inflow / Infiltration (I/I) of groundwater and stormwater.

d. Flow capacity increase due to Warren Epoxy’s Low Coefficient Of Roughness (COF) Vs. Shotcrete’s High COF.

new composite pipe with resistance to creep rupture and fatigue failure.

c. A durable barrier against potential Inflow / Infiltration (I/I) of groundwater and stormwater.

d. Flow capacity increase due to Warren Epoxy’s Low Coefficient Of Roughness (COF) Vs. Shotcrete’s High COF.

Structural Rehabilitation & Impermeabilization of two structurally deteriorated elevated steel tank silos a the medicinal gas manufacturing plant ACROMAX.

Brief Description of Selective Study Case No. 7:

The age of each of the elevated Carbon Steel Tank Silos was approximately 25 years old. They stored and operated a hot mix solution

of calcium hydroxide and water. Engineering assessment inspections identified many corrosion problems, structural deterioration, and

imperfect and irregular welds on the substrate to be coated.

Subsequently, a wet sandblasting surface preparation was done to generate the anchoring profile and required cleanliness for applying the

coating. All required structural repairs were performed, including removal of imperfect and irregular welds were removed. The Warren Epoxy was sprayed, and the average coating thickness was 1/8” (3 millimeters). Quality Control & Quality Assurance and inspections

were performed and they all passed with outstanding values.

manner, with no safety issues, and within the agreed work schedule with the customer. During the implementation of the project, the plant was able to continue operating at 50% capacity without stopping production. MADERO’s execution of this turnkey Mission Critical Project was a total success.

of calcium hydroxide and water. Engineering assessment inspections identified many corrosion problems, structural deterioration, and

imperfect and irregular welds on the substrate to be coated.

PRODUCT APPLICATION

As part of the surface preparation, high and ultra-high pressure jets of water (Range: 25,000 to 40,000 Psi) were applied to the silo internals for removing deposits of Calcium Hydroxide, which was solidified and strongly adhered to the substrate of the two tanks.Subsequently, a wet sandblasting surface preparation was done to generate the anchoring profile and required cleanliness for applying the

coating. All required structural repairs were performed, including removal of imperfect and irregular welds were removed. The Warren Epoxy was sprayed, and the average coating thickness was 1/8” (3 millimeters). Quality Control & Quality Assurance and inspections

were performed and they all passed with outstanding values.

CONCLUSION

The Impermeabilization and Rehabilitation Project of the two silos were successfully executed in ten (10) days, in a quality and cost-effectivemanner, with no safety issues, and within the agreed work schedule with the customer. During the implementation of the project, the plant was able to continue operating at 50% capacity without stopping production. MADERO’s execution of this turnkey Mission Critical Project was a total success.

Corrosion & Impermeabilization Protection, Structural Rehabilitation/Repair of Semi Deteriorated & Fully Deteriorated Metallic & Concrete

Brief Description of Selective Study Case No. 6:

Process Piping Systems & Component with Rapid Cure, Smart & Durable Engineered Composite Pipe Repair Systems.

Pics. 1 & 2: Composite Structural Rehab/Repair of Fully Deteriorated 12” Dia. Corroded Pipe w/ Pinholes

Pics. 3 & 4: Composite Structural Rehab/Repair of Fully Deteriorated 14” Dia. Corroded Pipe w/ Pinholes

Pics. 5 & 6: Composite Structural Rehab/Repair of Semi Deteriorated 54” Dia. Corroded Pipe w/ 63% Wall Loss

Corrosion Protection Coating Application at Market Center Lift Station’s Atmospheric and Immersion

Brief Description of Selective Study Case No. 5:

Piping Systems at City of Terrell, Texas.

Per owner’s coating specification, Immersion Piping System required application of three layers of Sherwin Williams Macropoxy coating system (i.e. primer, intermediate, and topcoat). Atmospheric Piping System also required first two layers of Sherwin Williams’ Macropoxy coating and Polyurethane topcoat. MADEROs Scope Of Work also included Abrasive Surface Preparation with Dustless Sponge Jet Abrasive System, Quality Control Testing (e.g. Wet Gauge, Holiday, and Adhesion Pull) and Quality Assurance.

Per owner’s coating specification, Immersion Piping System required application of three layers of Sherwin Williams Macropoxy coating system (i.e. primer, intermediate, and topcoat). Atmospheric Piping System also required first two layers of Sherwin Williams’ Macropoxy coating and Polyurethane topcoat. MADEROs Scope Of Work also included Abrasive Surface Preparation with Dustless Sponge Jet Abrasive System, Quality Control Testing (e.g. Wet Gauge, Holiday, and Adhesion Pull) and Quality Assurance.

Major Structural Engineered Rehabilitation & Repair, and Structural Optimization of Fully Deteriorated Buried 96” Diameter Concrete Piping & 4’x4’ Square Concrete Manhole Structures.

Brief Description of Selective Study Case No. 4:

using Warren Structural Epoxy for Long Term Useful Operational Life. Asset Owner: City of Fort Worth. The newly Engineered Protective, Structural Rehabilitation & Repair provided full structural integrity plus additional benefits (but not limiting to):

A. Able to withstand all the applicable structural design basis loads of soil and hydro loads.

B. A durable barrier against potential Inflow / Infiltration (I/I) of groundwater and stormwater, and hydrogen sulfide attack.

C. Pipe flow capacity increase due to Warren Epoxy’s Low Coefficient Of Roughness (COF) Vs. Deteriorated Concrete’s High COF.

The following pictures provide a view of their As-Found & As-Left Conditions of the Rehabilitated/Repaired Structures:

B. A durable barrier against potential Inflow / Infiltration (I/I) of groundwater and stormwater, and hydrogen sulfide attack.

C. Pipe flow capacity increase due to Warren Epoxy’s Low Coefficient Of Roughness (COF) Vs. Deteriorated Concrete’s High COF.

The following pictures provide a view of their As-Found & As-Left Conditions of the Rehabilitated/Repaired Structures:

Major Structural Engineered Rehabilitation & Repair of a Structurally Deteriorated Sewer Treatment Plant located at an island in the Gulf of Mexico, Galveston County, Texas.

Brief Description of Selective Study Case No. 3:

In May 2019, MADERO Provided Turnkey Certified Engineering Design / Installation / QA & QC Testing & Inspections of MADERO’s Structural Warren Epoxy Liner on Wastewater Sewer Treatment Tanks (e.g. Clarifier, Aeration Basin, Digester, Chlorine Contact Chambers), Concrete/Brick Manholes, and Metal Pipes & Structural Beams. MADERO also applied Polyurethane Coating in specific atmospheric areas & Performed Inflow & Infiltration (I/I) Structural Repairs.

he plant was constructed around 2014. After five years of operation, its concrete and metal structures had accelerated corrosion & structural deterioration due to the surrounding aggressive marine environment, and hydrogen sulfide attack from processing sewer wastewater. Furthermore, in 2017, the sewer structures were coated with an elastomeric protective coating. After two years of service, the coating was fully deteriorated and delaminating.

In May 2019, MADERO Provided Turnkey Certified Engineering Design / Installation / QA & QC Testing & Inspections of MADERO’s Structural Warren Epoxy Liner on Wastewater Sewer Treatment Tanks (e.g. Clarifier, Aeration Basin, Digester, Chlorine Contact Chambers), Concrete/Brick Manholes, and Metal Pipes & Structural Beams. MADERO also applied Polyurethane Coating in specific atmospheric areas & Performed Inflow & Infiltration (I/I) Structural Repairs.

Major Structural Engineered Rehabilitation & Repair, and Structural Optimization of Fully Deteriorated Stormwater Piping System Stadium

Brief Description of Selective Study Case No. 2:

Uusing Structural Epoxy and High Strength Carbon Reinforced Polymer for Structurally Robust Long Term Useful Operational Life.

Asset Owner: University of Tennessee. The buried Non-Structural Shotcrete Stormwater Piping System segment was located about 60 feet below ground of 100+ years old Neyland Stadium, in Knoxville, Tennessee. The newly Engineered Protective and Structural Composite Piping System provides full structural integrity plus additional benefits (but not limiting to):

a. Able to withstand all the applicable structural design basis loads of soil and hydro loads.

b. High strength Carbon Fiber Reinforced Polymer provides a more robust long-term operating life by protecting the

new composite pipe with resistance to creep rupture and fatigue failure.

c. A durable barrier against potential Inflow / Infiltration (I/I) of groundwater and stormwater.

d. Flow capacity increase due to Warren Epoxy’s Low Coefficient Of Roughness (COF) Vs. Shotcrete’s High COF.

new composite pipe with resistance to creep rupture and fatigue failure.

c. A durable barrier against potential Inflow / Infiltration (I/I) of groundwater and stormwater.

d. Flow capacity increase due to Warren Epoxy’s Low Coefficient Of Roughness (COF) Vs. Shotcrete’s High COF.

[pap_portfolio]

BE SURE TO GET THE LASTEST EXCLUSIVES OFFERS, PRODUCT RELEASES AND SO MUCH MORE

We have a professional team of manufacturing accountants and auditors for your company

What our clients are saying about our company and products

Ernest Smith

Construction Worker

Thomas Smith

CEO & Engineer

We believe architecture and design are critically important to addressing the most pressing challenges of our time.

Monica Smith

CEO & Architect

We believe architecture and design are critically important to addressing the most pressing challenges of our time.

Ernest Smith

Construction Worker

Great experience and impressive product. It was a very professional and technically competent job from the whole team.

Thomas Smith

CEO & Engineer

We believe architecture and design are critically important to addressing the most pressing challenges of our time.

Monica Smith

CEO & Architect

We believe architecture and design are critically important to addressing the most pressing challenges of our time.

Ernest Smith

Construction Worker

Great experience and impressive product. It was a very professional and technically competent job from the whole team.

Thomas Smith

CEO & Engineer

We believe architecture and design are critically important to addressing the most pressing challenges of our time.

Monica Smith

CEO & Architect

We believe architecture and design are critically important to addressing the most pressing challenges of our time.

BE SURE TO GET THE LASTEST EXCLUSIVES OFFERS, PRODUCT RELEASES AND SO MUCH MORE

Sign up and subscribe to our newsletter and get inspired every month

[mc4wp_form]

Great experience and impressive product. It was a very professional and technically competent job from the whole team.